The global demand for pharmaceuticals, fresh food, and other temperature-sensitive products is steadily increasing. To meet this demand, businesses rely on cold chain logistics, a specialized supply chain system that ensures products remain within a defined temperature range from origin to destination. From life-saving vaccines to fresh seafood, cold chain logistics plays a critical role in maintaining quality, safety, and compliance. In 2025, with rising consumer expectations and stricter regulations, the importance of reliable cold chain logistics has never been greater.

What is Cold Chain Logistics

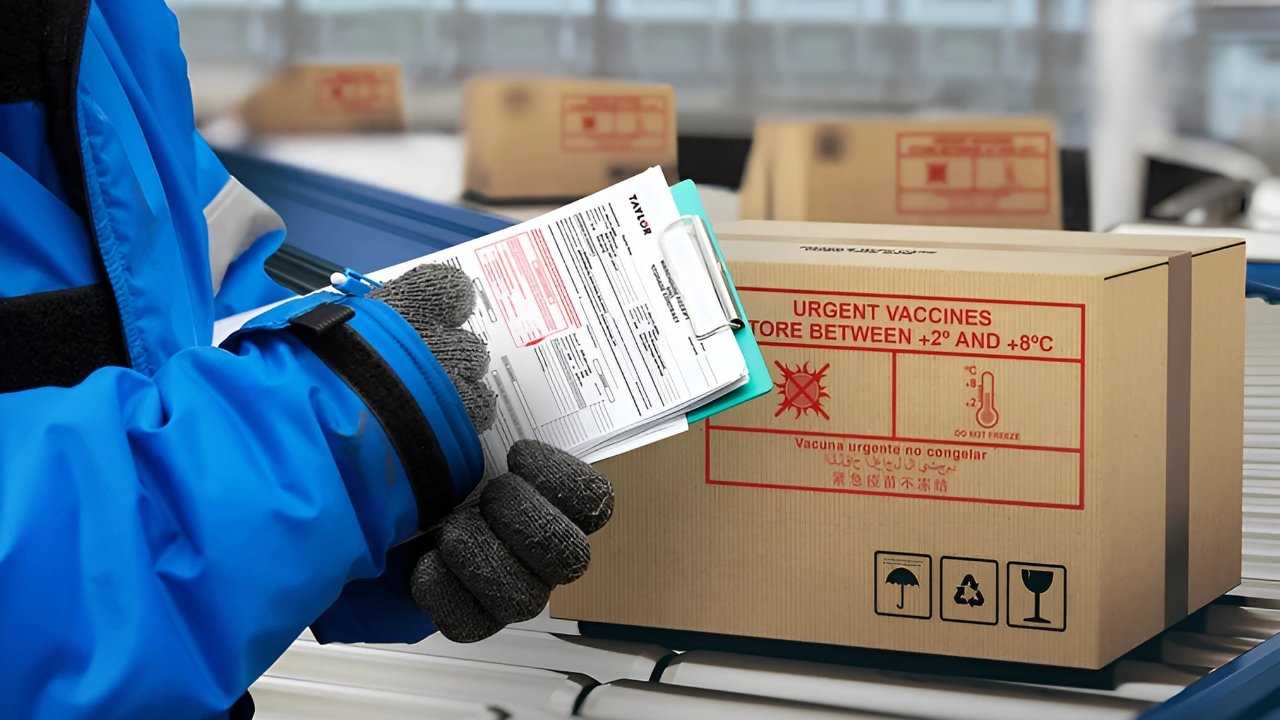

Cold chain logistics refers to the transportation, storage, and distribution of products that require controlled temperatures to maintain their integrity. This system involves refrigerated warehouses, temperature-controlled vehicles, insulated packaging, and continuous monitoring technologies. Without an efficient cold chain, products risk spoilage, loss of effectiveness, and safety concerns.

Importance in the Pharmaceutical Industry

Pharmaceutical products like vaccines, insulin, and biologics must be transported under strict temperature conditions. Even slight deviations can reduce their effectiveness or render them unsafe. Cold chain logistics ensures these medicines remain stable throughout their journey. With the global distribution of COVID-19 vaccines, the importance of cold chain infrastructure became evident, highlighting the need for investment in advanced solutions.

Importance in Perishable Goods

Perishable products such as dairy, fruits, vegetables, meat, and seafood have limited shelf lives. Cold chain logistics prevents spoilage by keeping these products fresh until they reach consumers. For exporters, particularly in the food sector, reliable cold chains open up opportunities to access international markets without compromising quality.

Key Challenges in Cold Chain Logistics

Temperature Variations

Maintaining consistent temperatures during loading, transportation, and unloading is one of the biggest challenges. Any fluctuation can damage sensitive goods.

Infrastructure Gaps

In many regions, especially developing countries, there is a lack of adequate cold storage facilities and refrigerated transport vehicles. This creates bottlenecks in supply chains.

High Operational Costs

Cold chain logistics requires specialized equipment and continuous monitoring, which increases costs compared to traditional logistics. Businesses often struggle to balance affordability with quality.

Compliance and Regulations

Pharma and food industries are subject to strict global standards. Companies must ensure their cold chain systems meet regulatory requirements, which can be complex and resource-intensive.

Innovations Driving Cold Chain Logistics

IoT and Real-Time Monitoring

Internet of Things (IoT) sensors provide continuous tracking of temperature, humidity, and location. These devices send alerts if conditions deviate, allowing corrective action before goods are damaged.

Advanced Packaging Solutions

Insulated containers and phase change materials are being used to extend the cooling effect during transportation. Such innovations reduce dependence on external refrigeration systems.

Refrigerated Vehicles and Drones

Specialized refrigerated trucks ensure goods remain within safe temperatures throughout the journey. In remote areas, drones equipped with cooling technology are being tested for delivering vaccines and small consignments of perishables.

Automation and AI in Warehousing

Cold storage warehouses are increasingly adopting automated systems for handling and tracking goods. AI helps forecast demand, reducing wastage and optimizing space usage.

Cost and Efficiency Benefits

While cold chain logistics involves higher costs, it also prevents major losses. Spoiled vaccines or perished food not only cause financial damage but also impact public health and customer trust. By investing in advanced cold chain solutions, companies can improve efficiency, reduce wastage, and open doors to new markets. In the long run, these savings outweigh the initial expenses.

Sustainability in Cold Chain Logistics

Environmental impact is another critical concern. Refrigeration systems often rely on high-energy consumption and harmful refrigerants. To address this, companies are moving towards eco-friendly cooling technologies, renewable energy-powered warehouses, and sustainable packaging. Green cold chain practices not only reduce emissions but also align with global sustainability goals.

Future Outlook

By 2025 and beyond, cold chain logistics will see wider adoption of AI, blockchain, and renewable energy technologies. Blockchain will ensure transparency by recording every stage of the journey, while renewable-powered cold storage will reduce costs and emissions. With the continued growth of pharma exports and rising demand for fresh food, cold chain networks will expand deeper into tier-2 and tier-3 cities, ensuring safer deliveries to a wider consumer base.

Conclusion

Cold chain logistics is the backbone of safe and efficient transport for pharmaceuticals and perishable goods. By ensuring strict temperature control, it safeguards product quality, consumer safety, and business reputation. Despite challenges such as infrastructure gaps and high costs, innovations in technology and sustainable practices are reshaping the industry. In the years ahead, companies that invest in reliable cold chain systems will not only gain a competitive edge but also play a vital role in protecting health and meeting the rising demand for fresh and safe products worldwide.